Manufacturing 4.0 leverages AI, IoT, and digital technologies to create smarter factories focused on predictive maintenance and process optimization. You can use sensors and real-time data to detect equipment issues early, reducing downtime and waste. AI analyzes patterns for quality control, while digital twins simulate scenarios for better decision-making. If you’re interested in how these innovations can transform your operations, there’s much more to explore.

Key Takeaways

- AI enables real-time monitoring and analysis of manufacturing processes to detect defects and optimize production.

- Predictive maintenance uses AI-driven data to forecast equipment failures, reducing downtime and maintenance costs.

- IoT sensors collect continuous data on machine performance, feeding AI algorithms for proactive decision-making.

- Digital twins, enhanced by AI, simulate equipment behavior for better planning and preventive actions.

- Implementing AI and predictive maintenance requires workforce upskilling, cybersecurity measures, and phased deployment strategies.

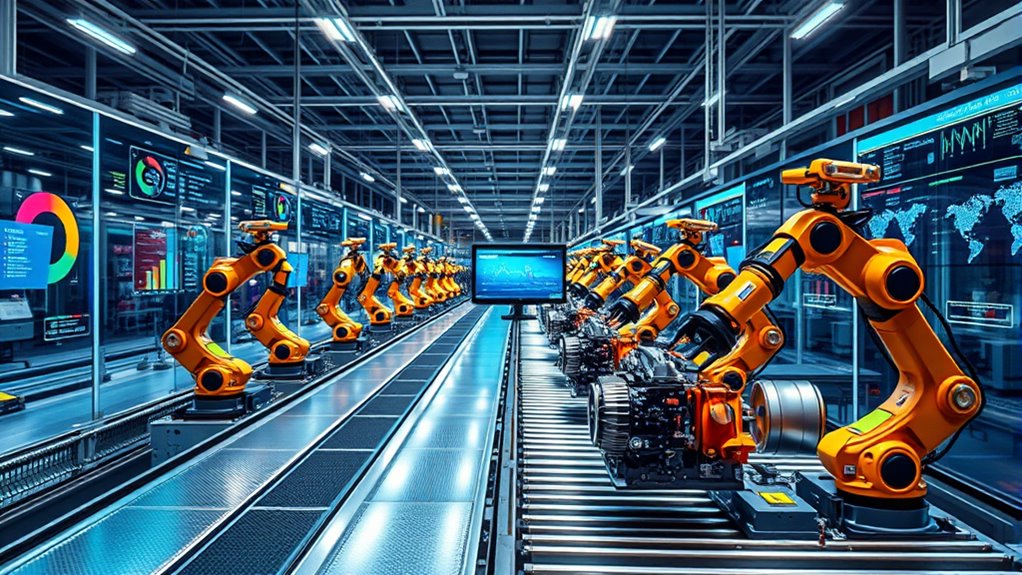

The Evolution of Industry 4.0 and Smart Manufacturing

The evolution of Industry 4.0 marks a significant shift in manufacturing, driven by the integration of advanced digital technologies. You now have access to smarter factories that leverage IoT, AI, cloud computing, and automation. These innovations enable real-time data collection, analysis, and decision-making, transforming traditional processes. As a result, manufacturing becomes more agile, efficient, and responsive to market demands. You’ll notice improved quality control, reduced cycle times, and cost savings through predictive maintenance. Digital twins and 5G connectivity further enhance operational visibility and speed. This digital transformation empowers you to optimize resource management and streamline your supply chains. Overall, Industry 4.0 ushers in a new era where technology shapes every aspect of manufacturing, making it more intelligent and adaptive. Incorporating advanced manufacturing techniques enhances overall system performance and supports continuous innovation. Additionally, understanding cybersecurity is crucial to protect interconnected systems from potential threats in these digital environments.

How AI Enhances Quality Control and Process Optimization

AI revolutionizes quality control and process optimization by enabling real-time monitoring and analysis of manufacturing operations. This allows you to detect defects instantly, reducing waste and rework. AI algorithms analyze data from sensors and cameras to identify patterns and anomalies, helping you prevent issues before they escalate. As a result, you can fine-tune processes, improve yield, and ensure consistent product quality. Leveraging AI content clusters enhances the overall effectiveness of these strategies by facilitating deeper insights and targeted improvements.

The Role of IoT and Sensors in Predictive Maintenance

IoT and sensors play a crucial role in predictive maintenance by providing real-time data on machine performance and environmental conditions. This data helps you detect issues early, schedule maintenance proactively, and reduce unexpected failures. Sensors track parameters like temperature, vibration, and pressure, giving you clear insights into equipment health. The data collected enables better decision-making and minimizes downtime. To illustrate, consider this table:

| Sensor Type | Data Monitored | Benefits |

|---|---|---|

| Vibration Sensors | Machine vibrations | Detects imbalance or misalignment |

| Temperature Sensors | Operating temperature | Prevents overheating |

| Pressure Sensors | Hydraulic/pneumatic systems | Ensures optimal functioning |

| Humidity Sensors | Environmental conditions | Maintains proper conditions |

| Proximity Sensors | Position detection | Monitors component placement |

Additionally, understanding the sensor technology used in your setup can significantly enhance the accuracy and reliability of your predictive maintenance system. Incorporating advanced sensor calibration techniques can further improve data accuracy and system performance.

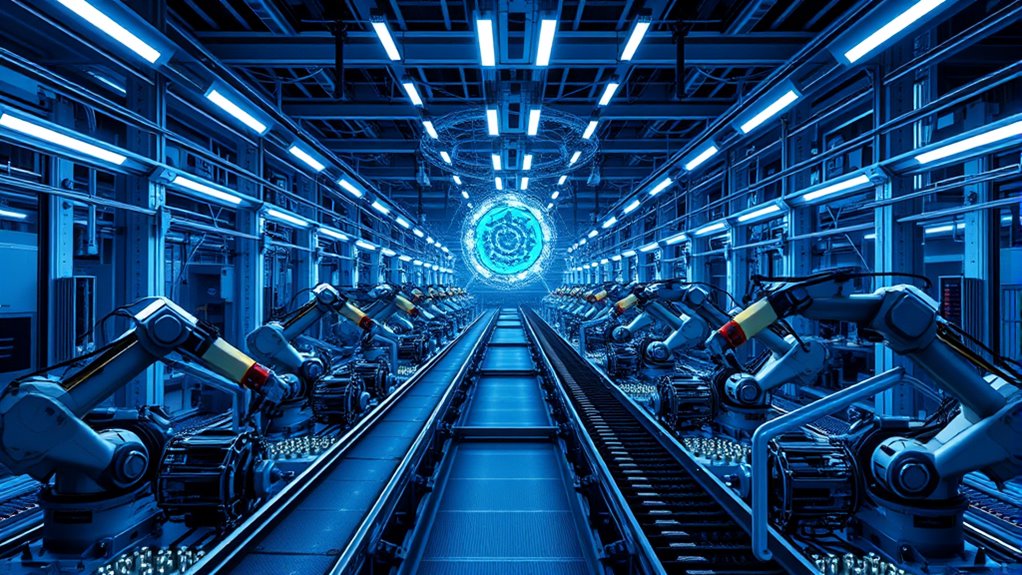

Technological Foundations Driving Manufacturing Innovation

You play a key role in leveraging Industry 4.0 technologies like IoT, AI, and cloud computing to transform manufacturing. Digital twins and real-time connectivity enable you to simulate, monitor, and optimize processes more effectively. Embracing these innovations drives efficiency, reduces costs, and sparks ongoing manufacturing breakthroughs. Incorporating predictive maintenance practices can also improve focus and decision-making, contributing to more mindful management of complex systems. For example, understanding signs of spoilage in raw materials can prevent disruptions and waste, aligning with proactive maintenance strategies. Additionally, understanding home furnishings safety can inform the design of safer manufacturing environments, reducing workplace hazards. Furthermore, fostering personal development techniques can foster continuous learning and adaptability within manufacturing teams, enhancing overall resilience.

Core Industry 4.0 Technologies

Industry 4.0 revolutionizes manufacturing by integrating cutting-edge technologies that enable smarter, more efficient production processes. These core technologies form the backbone of modern factories, driving innovation and competitiveness. You’ll leverage the Internet of Things (IoT) to connect machines and collect real-time data, enhancing operational visibility. Cloud computing offers scalable data storage and analytics, allowing quick decision-making. AI and machine learning analyze data patterns, optimize processes, and enable predictive insights. Understanding these foundational tools helps you implement smarter systems. Consider these key aspects:

- IoT creates interconnected machinery for seamless data flow.

- Cloud platforms facilitate centralized data analysis and remote management.

- AI-driven insights enable proactive decision-making, reducing waste and downtime.

- Incorporating natural materials into manufacturing environments can improve sustainability and worker well-being. Additionally, integrating emotional support strategies can promote a healthier work environment, boosting employee satisfaction and productivity.

Mastering these technologies unbars manufacturing’s full potential and accelerates your Industry 4.0 journey.

Digital Twins and Connectivity

Digital twins and connectivity are transforming manufacturing by creating highly accurate virtual replicas of physical assets and systems. This technology allows you to simulate, monitor, and optimize operations in real-time, reducing downtime and improving efficiency. With digital twins, you can predict how equipment will perform under different conditions, enabling proactive maintenance and minimizing unexpected failures. This proactive approach enhances operational reliability and reduces costs associated with unplanned repairs. Connectivity, especially through IoT and 5G, ensures seamless data flow between physical assets and digital models, fostering faster decision-making. You can remotely troubleshoot issues, test upgrades, and optimize workflows without physical intervention. This integration boosts transparency across your supply chain, enhances collaboration, and accelerates innovation. As connectivity improves, digital twins become more precise and responsive, driving continuous improvement and delivering significant cost savings across manufacturing processes. Incorporating real-time data from connected devices further enhances the accuracy and effectiveness of digital twins, enabling more dynamic and predictive insights. Additionally, the integration of advanced sensors helps capture detailed data, further refining the virtual models for better predictive capabilities. The use of standardized communication protocols ensures compatibility and smooth data exchange between diverse systems, further optimizing manufacturing operations. Emphasizing interoperability is essential for integrating various systems seamlessly and maximizing the benefits of digital twin technology.

Economic Benefits and Strategic Advantages of Digital Transformation

Adopting advanced manufacturing technologies delivers significant economic benefits and strategic advantages that can transform your business. Digital transformation boosts productivity, reduces costs, and enhances competitiveness. You can expect improved operational efficiency through real-time data and automation, leading to faster decision-making. It also enables you to better meet customer demands with higher quality products and shorter lead times. Additionally, digitalization helps you stay ahead by fostering innovation and agility, which are vital in a rapidly changing market. Embracing innovations such as quantum computing advancements can further enhance data processing capabilities, giving your enterprise a competitive edge through innovation. Moreover, integrating headphones and audio technology into manufacturing processes can improve communication and monitoring in complex environments, ensuring high standards of quality and safety. Leveraging digital twins can also optimize production processes by simulating and predicting system behaviors before implementation.

Workforce Transformation and Skills Development in Smart Factories

As manufacturing becomes smarter and more automated, the workforce must evolve alongside these technological advancements. You’ll need new skills like coding, data analysis, and system management, while manual tasks decline. Upskilling workers and recruiting specialists become essential to bridge the skills gap. Training programs must focus on digital literacy, robotics, and AI tools to keep your team competitive. Embracing AI Bifurcation insights can help organizations understand the shifting landscape of human and artificial intelligence roles in manufacturing. Additionally, understanding Vetted – Grobal World trends in smart technology adoption can inform strategic workforce planning.

Overcoming Barriers: Challenges in Implementing AI-Driven Manufacturing

Implementing AI-driven manufacturing faces significant hurdles, primarily due to high upfront investments and complex integration processes. You’ll need substantial capital to upgrade infrastructure, update legacy systems, and deploy new technologies. Compatibility issues can slow progress, as integrating IoT, AI, and automation requires seamless interoperability. Additionally, finding skilled workers remains a challenge, as a skills gap exists in robotics, data analytics, and cybersecurity. To overcome these barriers, consider:

- Prioritizing phased implementation to manage costs and reduce risk.

- Investing in staff training and recruiting specialists to bridge skill gaps.

- Developing robust cybersecurity measures to protect connected systems.

- Addressing cheating in workforce management can help foster a trustworthy environment, supporting successful AI integration.

Addressing these challenges proactively helps you better navigate the shift, maximize ROI, and unleash the full potential of AI-driven manufacturing.

Frequently Asked Questions

What Are the Key Cybersecurity Concerns for Ai-Driven Factories?

You should be aware that cybersecurity concerns in AI-driven factories include increased vulnerability to cyberattacks targeting connected devices, sensors, and networks. These attacks can disrupt production, steal sensitive data, or cause safety issues. Weak security protocols and outdated systems heighten risks. To protect your operations, implement robust security measures like encryption, regular updates, intrusion detection systems, and employee training to mitigate these threats effectively.

How Do Legacy Systems Impact Industry 4.0 Adoption?

Legacy systems limit your leap into Industry 4.0 by causing compatibility conundrums, complicating connectivity, and creating costly chaos. They often resist seamless integration, impede innovation, and inflate infrastructure investments. You face formidable friction fitting outdated frameworks with fresh, flexible technologies. Overcoming these obstacles demands diligent dedication to digital transformation, dynamic upgrades, and decisive decommissioning, all aimed at streamlining systems, strengthening security, and ensuring a smooth, scalable, and secure smart factory journey.

What Strategies Are Effective for Workforce Upskilling in Smart Manufacturing?

You should focus on targeted training programs that combine technical skills like coding and analytics with soft skills like problem-solving. Partner with educational institutions or industry experts to develop continuous learning pathways. Encourage hands-on experience through simulations or apprenticeships, and promote a culture of adaptability. Regularly assess skill gaps, update training content, and incentivize employees to embrace digital transformation, ensuring your workforce stays competent and motivated in smart manufacturing environments.

How Does Data Interoperability Affect AI Integration in Manufacturing?

You might worry that data interoperability is too complex, but it’s essential for seamless AI integration. When systems can’t communicate, AI models struggle to access reliable data, causing delays, errors, and missed opportunities. By prioritizing interoperability, you guarantee smooth data flow across platforms. This opens AI’s full potential, boosts efficiency, and drives innovation, making your smart factory more agile, competitive, and capable of delivering real-time insights that transform operations.

What Are the Costs and ROI of Implementing Digital Supply Chains?

You’ll find that implementing digital supply chains involves significant upfront costs for technology, infrastructure, and training. However, the ROI is compelling—you’ll gain better visibility, reduced lead times, and lower inventory costs. Expect increased efficiency, faster decision-making, and improved customer satisfaction, leading to higher profits over time. While initial investments are high, the long-term benefits of streamlined operations and data-driven insights make digital supply chains a smart strategic move.

Conclusion

As you embrace Manufacturing 4.0, remember that over 75% of manufacturers report significant improvements in efficiency thanks to AI and IoT integration. By adopting these smart technologies, you can enhance quality, reduce downtime, and stay competitive in a rapidly evolving market. Embrace digital transformation today to open new opportunities, streamline operations, and secure your position in the future of manufacturing. The future is now—don’t get left behind.