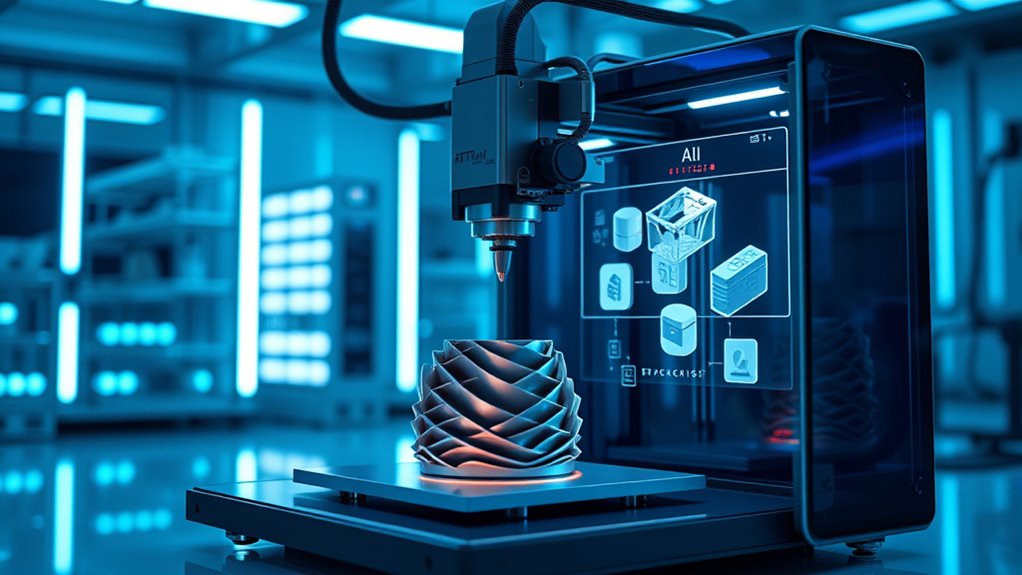

AI is transforming 3D printing by enabling smarter designs, real-time process control, and faster material development. It helps you create complex geometries through generative and topology optimization, while monitoring and adjusting printing parameters on the fly to reduce errors. AI also predicts equipment failures, streamlines workflows, and accelerates new material innovation. With ongoing advancements, you’ll discover how AI continues to push the boundaries of what’s possible in 3D printing technology.

Key Takeaways

- AI enables complex geometry design and topology optimization for innovative 3D printed structures.

- Real-time AI monitoring improves print quality and reduces defects through adaptive process control.

- Predictive maintenance powered by AI minimizes downtime and enhances workflow efficiency.

- AI accelerates material development by predicting properties and optimizing new material compositions.

- Data analysis and cybersecurity tools safeguard proprietary data and optimize production processes.

Artificial intelligence is transforming 3D printing by making processes faster, more precise, and more innovative. With AI-driven design and topology optimization, you can now create complex geometries that were once impossible using traditional methods. Generative design tools powered by AI help you explore countless design options quickly, suggesting innovative shapes and structures that maximize strength while minimizing material use. This means you can produce lightweight yet durable components that meet or exceed performance requirements. AI algorithms also allow you to experiment with new material combinations and advanced alloys, pushing the boundaries of what’s achievable in 3D printed parts. By accelerating the ideation process, AI provides intelligent suggestions and optimizations, reducing the time from concept to final design. It also predicts manufacturability issues early, helping you avoid costly errors during production and decreasing the number of design iterations needed. Furthermore, integrating Automation in Manufacturing enhances the overall efficiency of the 3D printing workflow. Additionally, AI-driven data analysis supports cybersecurity by safeguarding proprietary designs and sensitive manufacturing data against cyber threats throughout the process. Incorporating noise levels monitoring in 3D printing environments helps maintain optimal conditions and prevent equipment malfunctions. In real-time, AI enhances process monitoring and control. Machine learning models, utilizing computer vision, keep a close eye on the printing process, detecting errors as they happen. When deviations are identified, AI systems can adjust parameters like print speed and material deposition dynamically, minimizing defects and ensuring higher accuracy. This real-time oversight reduces the trial-and-error traditionally associated with fine-tuning print settings, saving you time and resources. As a result, the consistency and reliability of even the most complex prints markedly improve, giving you confidence that each piece will meet specifications without extensive manual intervention. AI also plays an essential role in quality assurance and predictive maintenance. By analyzing data from each print, AI predicts potential defects before they happen, enabling you to take preventive actions. This proactive approach minimizes waste and streamlines inspections, making quality checks faster and more accurate. Additionally, AI-driven predictive models schedule maintenance before equipment failures occur, preventing unexpected downtimes that could delay your projects. This integration reduces your reliance on costly post-production inspections by embedding quality controls throughout the workflow, ensuring higher overall product quality. Furthermore, AI accelerates material innovation. Advanced models predict properties of new materials and complex alloys, reducing the need for extensive experimental testing. This speeds up the development of specialized materials tailored for specific applications like aerospace or automotive industries. AI simulations help you understand how these novel materials behave during printing, allowing for better design and process optimization. Incorporating Material Testing into AI workflows can further enhance the development process. Moreover, leveraging machine learning models enables continuous improvement in printing accuracy and efficiency by analyzing accumulated data over time. Coupled with workflow optimization tools, AI identifies bottlenecks and inefficiencies in your production chain, supporting smarter decision-making that balances speed, cost, and quality. It automates routine tasks, freeing you to focus on higher-value activities, and fosters collaboration between humans and machines for a more streamlined, innovative 3D printing process.

Frequently Asked Questions

How Does AI Improve the Accuracy of 3D Printed Prototypes?

You want to know how AI makes your 3D printed prototypes more accurate. AI improves this by converting scans into precise models, refining designs, and reducing human errors. It detects defects early, predicts issues, and adjusts print settings in real-time. Plus, AI optimizes workflows, monitors quality continuously, and learns from failures, all of which lead to prototypes that are more reliable, detailed, and true to your original design.

Can AI Optimize Material Selection for Specific 3D Printing Projects?

Think of AI as a skilled navigator guiding your ship through uncharted waters. It can indeed optimize material selection for your 3D printing projects by analyzing vast data to find the perfect balance of strength, durability, and cost-effectiveness. AI utilizes neural networks and algorithms to predict how materials perform, ensuring you choose the most suitable options. This targeted approach saves time, reduces waste, and elevates your project’s success.

What Are Ai’S Limitations in Real-Time Defect Detection During Printing?

You might find that AI’s real-time defect detection has limitations. It struggles with processing large data quickly, which can cause delays. External factors like lighting or noise can interfere, reducing accuracy. AI models can produce false positives or negatives, missing defects or raising false alarms. Plus, integrating AI with existing printers can be complex and costly, and most systems can’t correct defects on the fly, only alert you to issues.

How Does AI Contribute to Reducing Material Waste in 3D Printing?

You might think 3D printing wastes a lot of material, but AI’s here to change that. It predicts the most efficient way to construct objects, designs support structures to minimize excess, and monitors prints in real time to cut waste. Plus, AI promotes recycled materials and optimizes designs for less material use, making your printing process smarter, greener, and way less wasteful—if only we’d listened to AI’s eco-friendly advice sooner.

Are There Ethical Concerns With Ai-Driven Automation in 3D Printing?

You should be aware that AI-driven automation in 3D printing raises ethical concerns. It can lead to job displacement, requiring workers to learn new skills. There are also risks related to intellectual property theft, security vulnerabilities, and unregulated production of dangerous items. Plus, data privacy and bias in AI systems pose additional challenges. It’s essential to implement proper safeguards, transparency, and regulation to address these issues responsibly.

Conclusion

As you explore AI’s role in 3D printing, you’ll see how it boosts efficiency and innovation. Did you know that AI-driven optimization can reduce material waste by up to 50%? This means not only faster production but also significant cost savings and sustainability benefits. Embracing AI in 3D printing opens doors to limitless possibilities—so stay curious and keep pushing the boundaries of what’s possible in this exciting field.